Benefits of

close-coupled flush rings

- Easy installation process

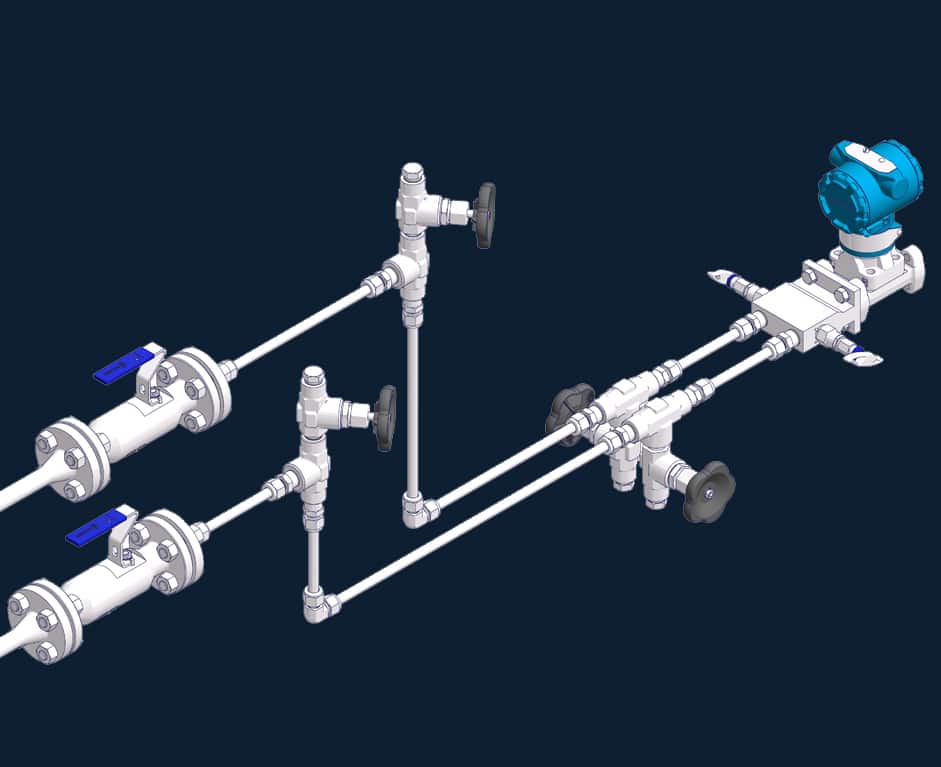

The impulse lines used for Traditional Flushing require lots of planning. They are also tricky and time consuming to install. Close-Coupled Flush Rings have a simple installation process using a direct connection to the process line without impulse lines. It is a true plug and play application.

- Reduced assembly time

With close coupling, engineers and technicians can start the assembling process right away. They don‘t lose time commissioning loose parts, bending pipes, and testing. Technicians can omit pressure trials on the measuring line.

- Minimized leakage

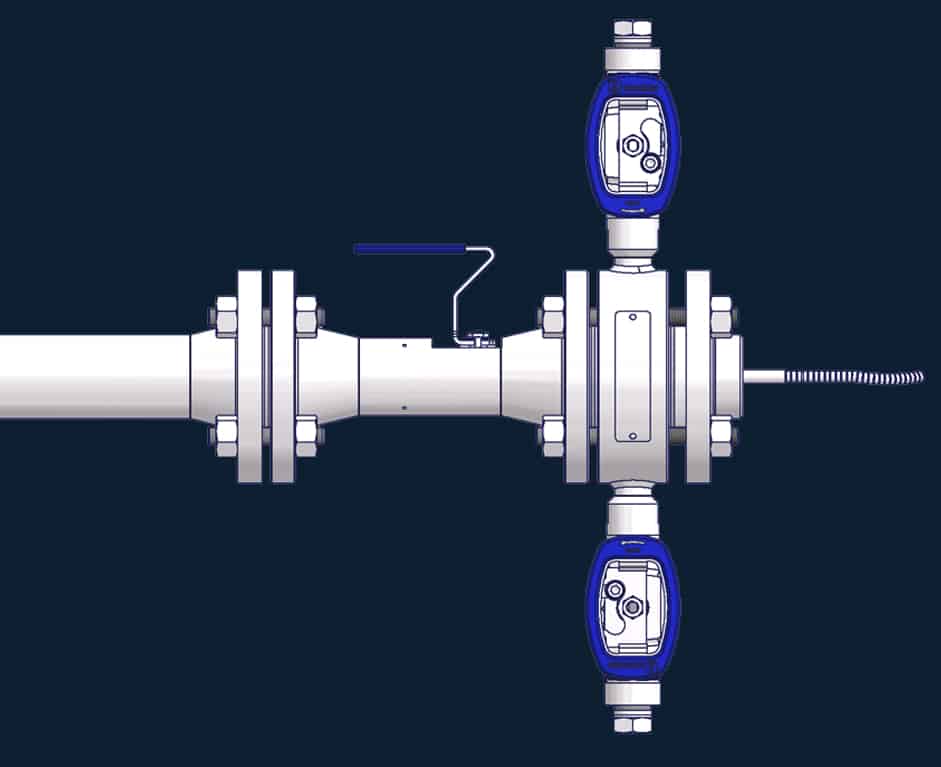

Close coupling also reduces the risk of leakage, a critical topic in the oil & gas, chemical, and petrochemical industries. These industries must provide leak-free and accurate storage of fuel, oil, gas, various chemicals and waste water. The holding capacity of the storage tanks is often several million liters. Leaks can be disastrous to both the company and the environment.

- Accurate measurement results

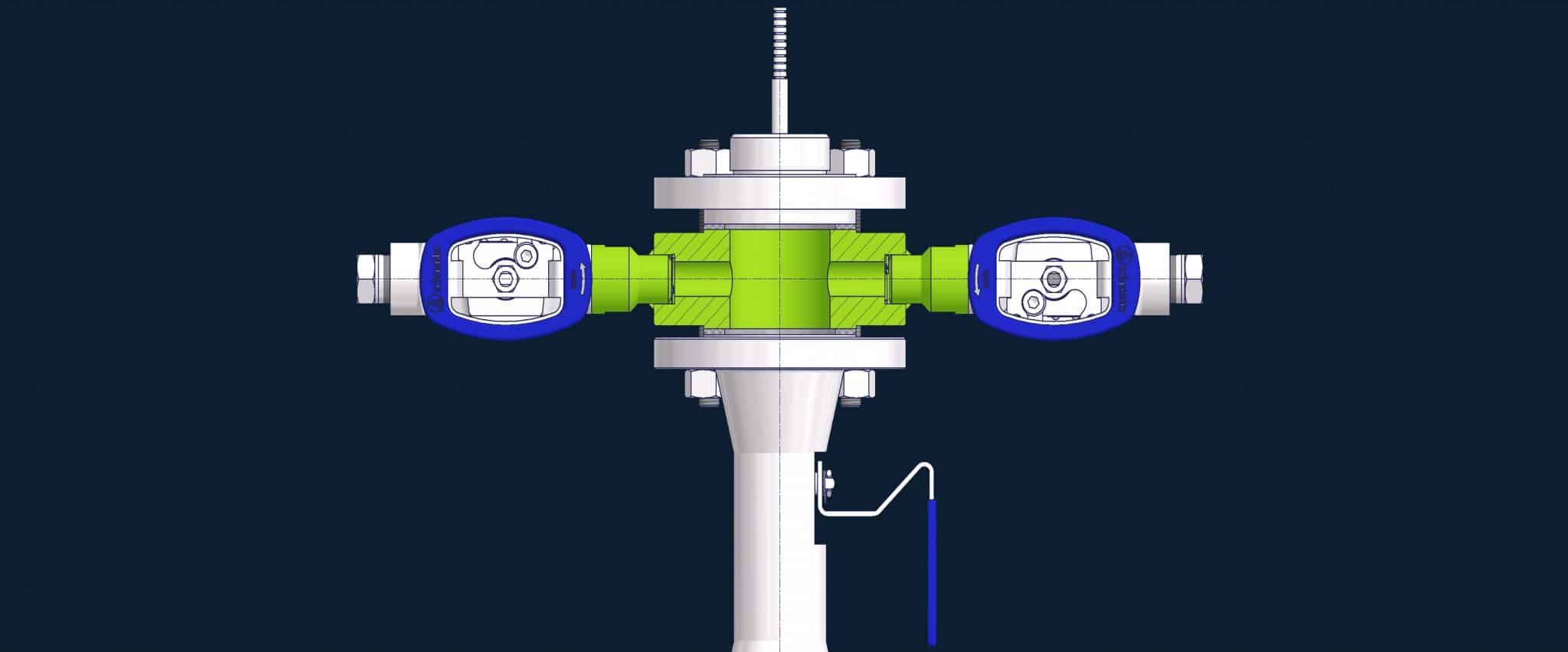

While the tight seal of the Close-Coupled Flush Rings reduces vibrations, a clean orifice is achieved by flushing. A combination of both result in a higher accuracy of measure.

- Safety standards

After the primary isolation valve is closed, a small amount of the pressurized medium remains in the pipeline section. This residual medium gets trapped between the primary isolation valve and the transmitter.

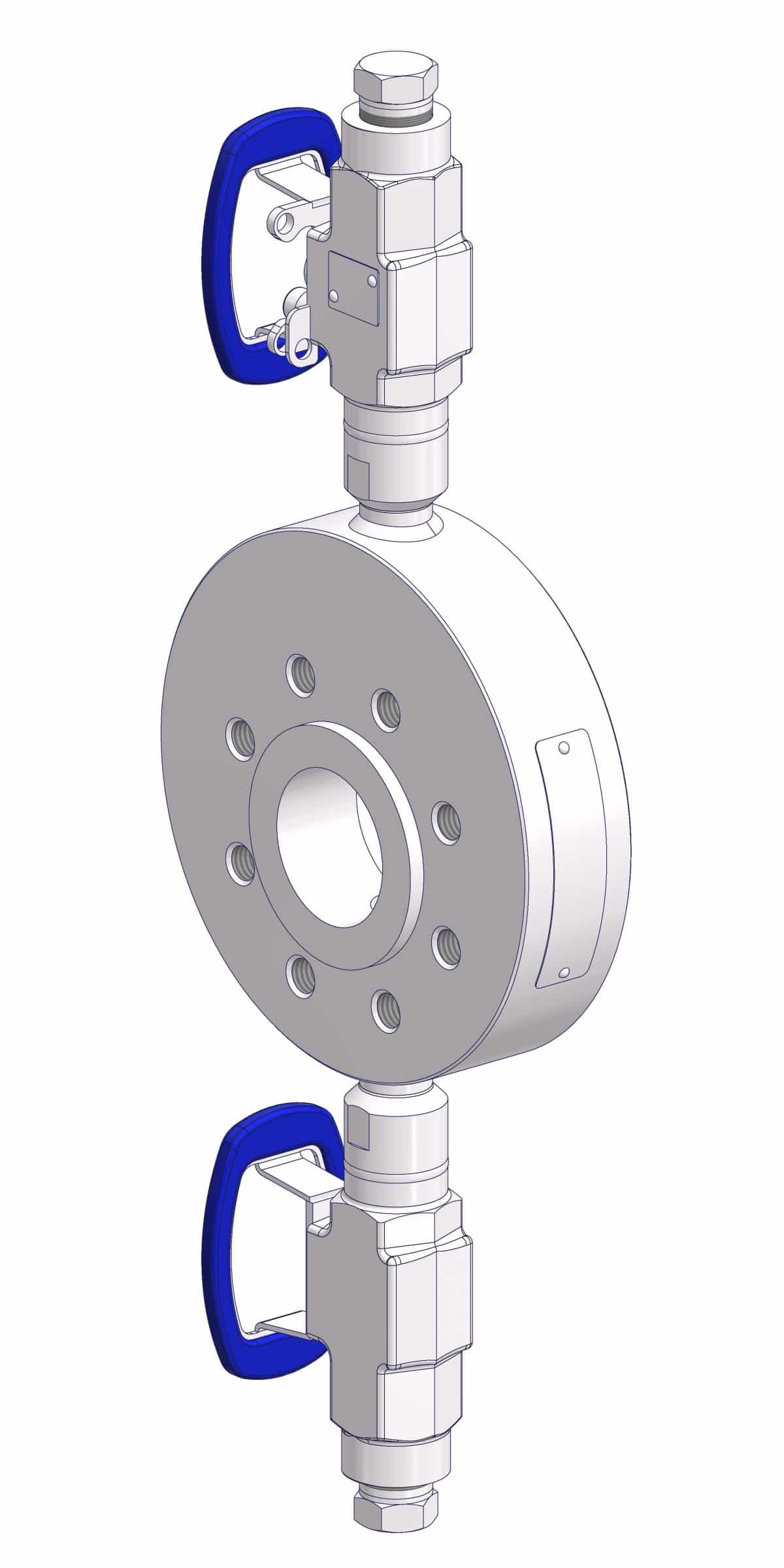

The operator must collect and dispose of this media in a manner that meets regulatory standards and without injury to health. Close-Coupled Flush Rings are a reliable method to empty the cavity between the primary isolation valve and transmitter.

- Environmental requirement

Some of the substances contained in the storage tanks are corrosive or toxic. Others are flammable or environmentally hazardous. The technician must ensure that there is a system to capture and dispose all such gases and liquids.

Proper disposal is a legal requirement. The only exceptions are nitrogen, oxygen, and drinking water. Flush Rings support operators to properly dispose of accumulating gas and liquid residues during maintenance and repair operations of measuring assemblies.