Benefits of

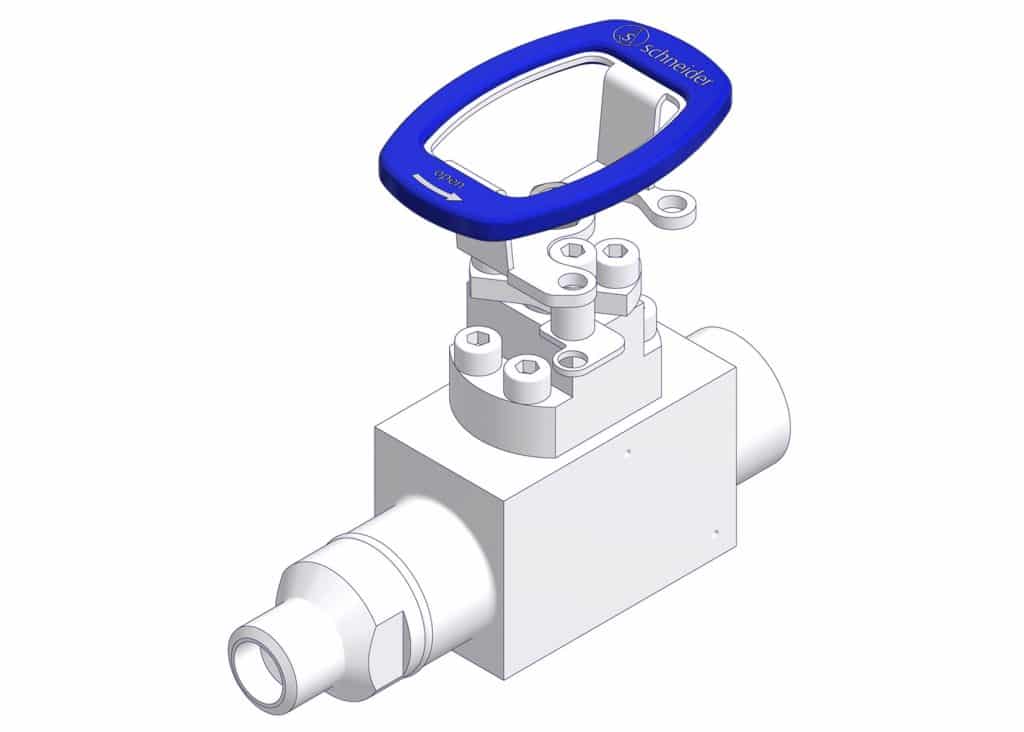

Instrumentation Ball Valves

- Direct Installation

All established connections types such as socket & butt welds, threads, I-flanges and ANSI flanges are available. In order to reduce emissions, all connection types are fully welded to the body.

- Materials

Special services are calling for special materials of the housing and sealing parts. AS-Schneider offer Instrumentation Ball Valves in a wide variety of materials. Forged carbon or stainless steel bodies, bar stock alloys, coated balls and different soft seats or gasket materials are standardized.

- Safety

The fully welded bodies in combination with an anti-blowout stem, anti-static design, fire safe approval and a lockable handle are as standard features and ensure safe operation at all times.

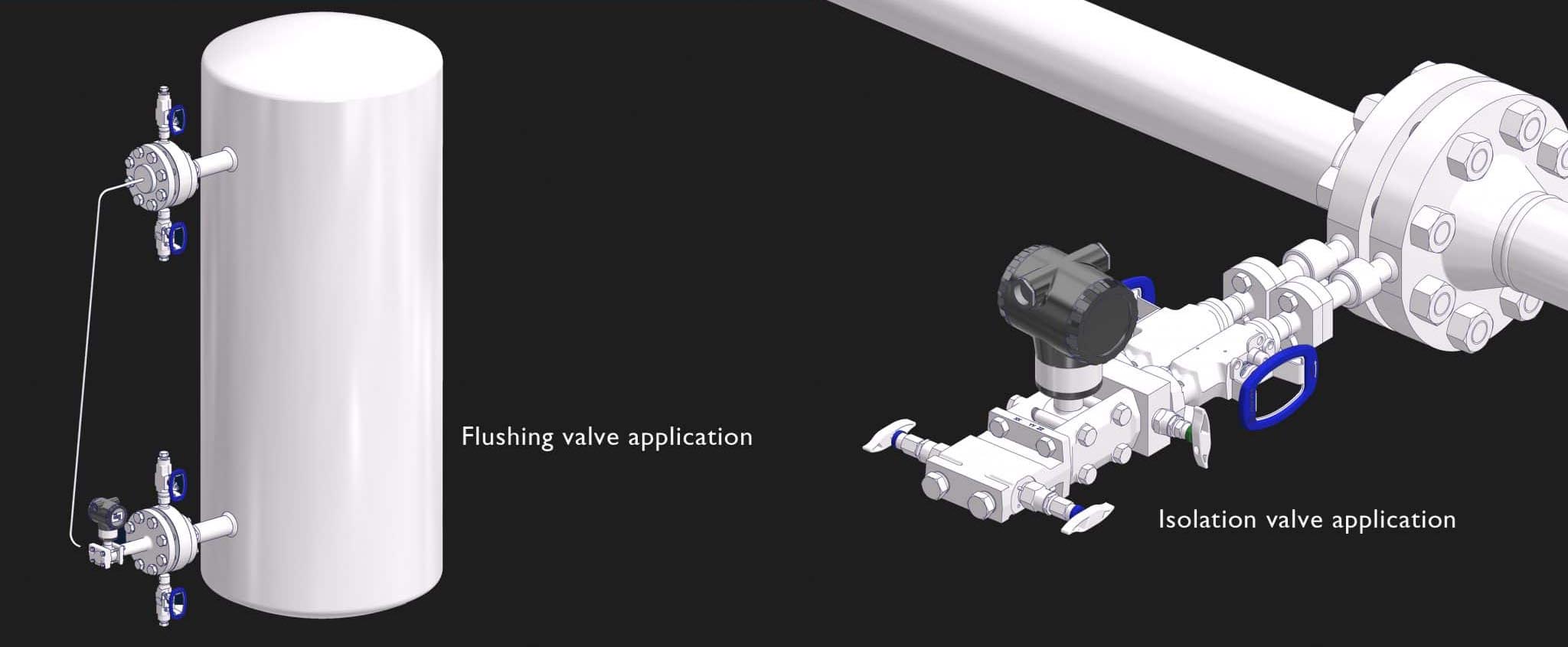

- Multifunctional

All items are produced in-house, modifications are no issue! No matter if an extended or oversized inlet is required or if the body should be designed as a multi-port with various outlets.

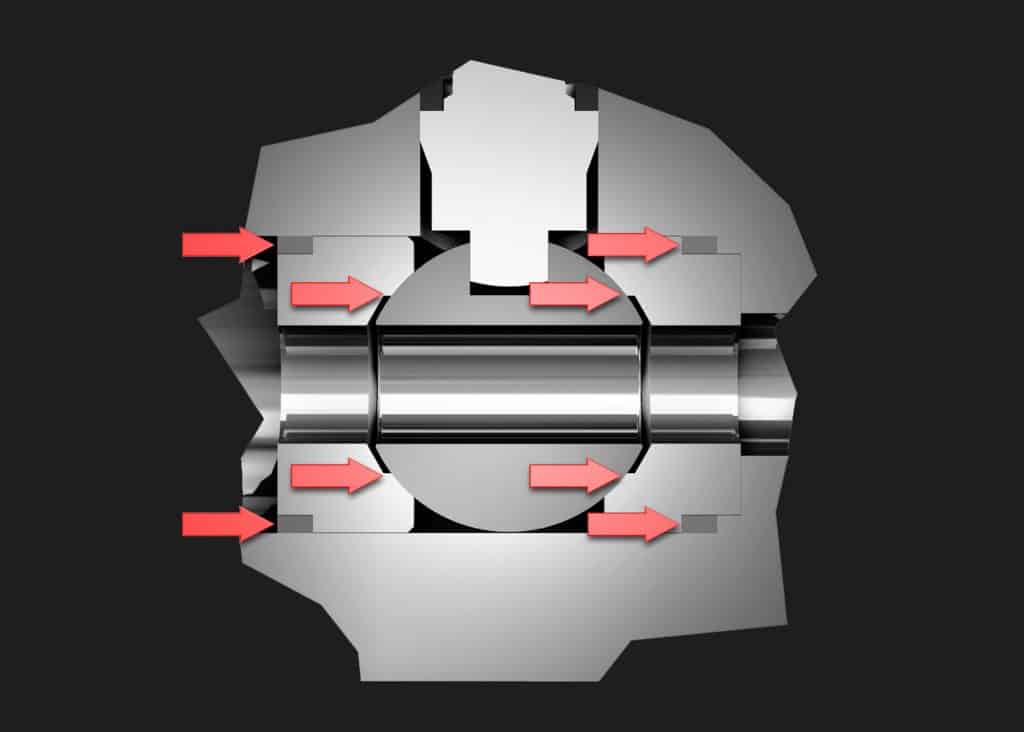

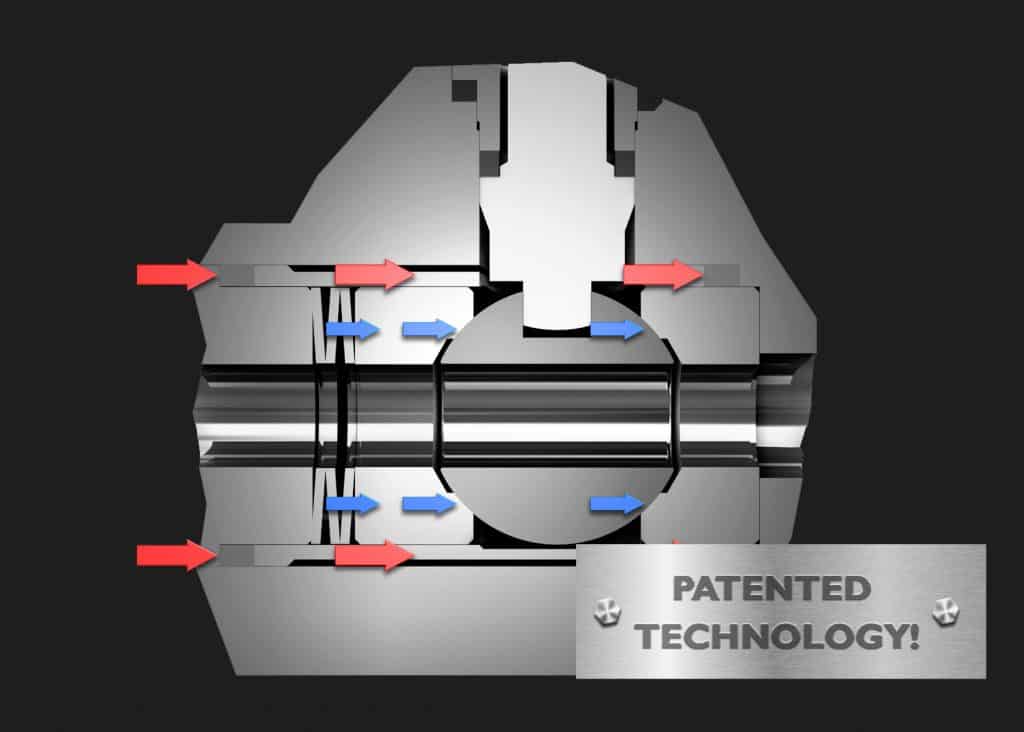

- Operating

The design and material of the parts in use are optimized to ensure smooth and easily operation.