Benefits of

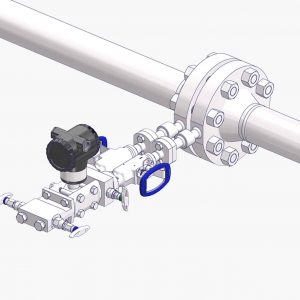

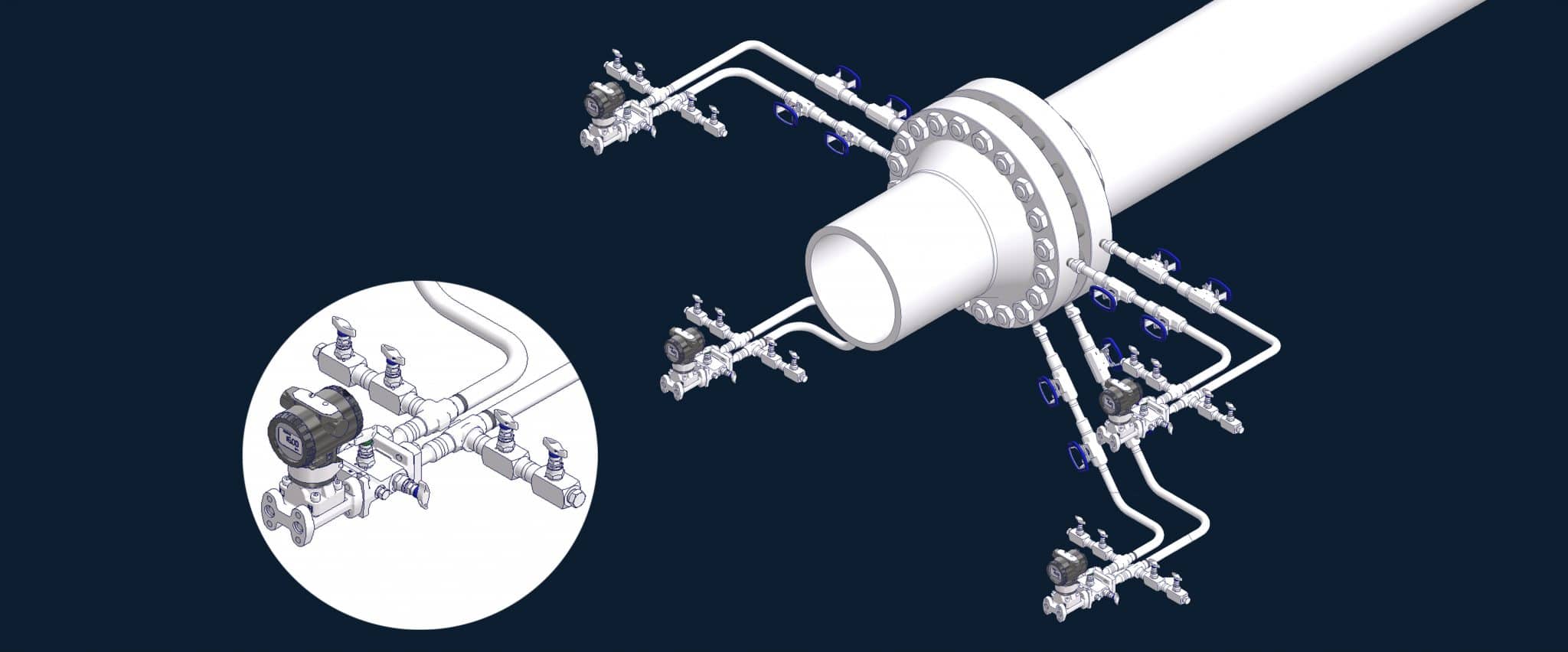

Close-coupled Installation Details

- Reduced assembly process

With Close-Coupled Installation Details, engineers and technicians can start the assembling process right away. They don‘t have to spend time commissioning loose parts, bending tubes and tightness testing. Instead, they just specify an application set including all accessories from only one supplier.

- Easy installation process

- Minimized leakage

Close coupling reduces the risk of leakage, a critical feature in the oil and gas, chemical, and petrochemical industries. These industries must provide storage for fuel, oil, gas, various chemicals and wastewater. The holding capacity of the storage tanks is often several million liters. Leaks can be disastrous to both the company and the environment.

- Reduced maintenance costs

As joints and threaded connections are minimized, the risk of loosened parts from vibration is reduced. With the use of ½” connections, distorted or even broken lines are not an issue anymore. Most items are coming with a straight bore or with replaceable soft seats, so lines can be cleaned and seats easily & quickly replaced. This leads to a lifetime extension and delay the need for new investments.

- Accurate measurements

With their compact welded designs, Close-Coupled Installation Details eliminate vibrations and unnecessary long distances to the measurement device. The results become more accurate and prevent miscalculations based on inaccurate information.

- Safety standards

To avoid trapped residual media in the application or an uncontrolled release, which both are potential dangers for human and environment, Close-Coupled Installation Details offer various options of a controlled release:

Small vent valves for pressure, plugs for liquids or plugged gate valves to shut-off and connect a hose.

The operator can collect and dispose of it in a manner that meets regulatory standards and therefore without injury to health.

- Environmental Requirement

Some of the substances contained in the measuring system are corrosive or toxic, others are flammable or environmental hazards. The technician must ensure the availability of a system to capture and dispose of all gases and liquids.

Proper disposal is a legal requirement. The only exceptions are nitrogen, and drinking water. The drain and vent options help operators to properly dispose of accumulated gas and liquid residues during the maintenance and repairs of measuring assemblies.